Mercedes frame alignment is a meticulous process that forms the basis for all repair work on Mercedes-Benz vehicles. By precisely straightening and realigning structural components, it ensures safety, handling, and performance—key attributes of the Mercedes brand. Using Mercedes-Benz Engineering Blueprints, technicians can restore structural integrity with exact measurements, optimizing vehicle performance and meeting high standards for body work and scratch repair. Proper alignment is crucial for preserving vehicle value through accurate painting, minimizing repair costs, and enhancing resale value.

Mercedes frame alignment is a critical process that ensures the structural integrity and safety of Mercedes vehicles. This intricate procedure follows precise engineering blueprints developed by Mercedes-Benz, setting a new standard for precision repair. By adhering to these guidelines, technicians can effectively realign damaged components, restoring the vehicle’s original specifications and performance. This article explores the importance of Mercedes frame alignment, the role of Mercedes-Benz Engineering blueprints, and best practices for achieving optimal results in Mercedes vehicles.

- Understanding Mercedes Frame Alignment: The Foundation of Precision Repair

- Mercedes-Benz Engineering Blueprints: Guiding the Alignment Process

- Benefits and Best Practices for Optimal Frame Alignment in Mercedes Vehicles

Understanding Mercedes Frame Alignment: The Foundation of Precision Repair

Mercedes frame alignment is a critical process that forms the foundation for precise repair work on Mercedes-Benz vehicles. It involves meticulously straightening and realigning the car’s structural components, ensuring they return to their original factory specifications. This meticulous procedure is essential in maintaining the vehicle’s safety, handling, and overall performance, which are hallmarks of the Mercedes-Benz brand.

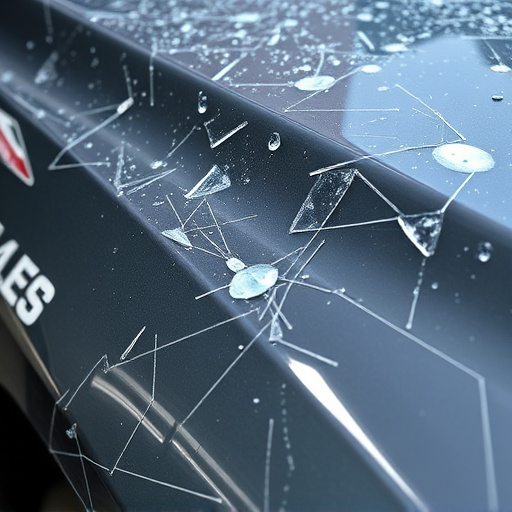

Proper frame alignment is crucial for effective auto body services, as it guarantees that any repairs or modifications are carried out with laser accuracy. Car bodywork experts use advanced equipment to measure and adjust various points on the frame, including wheels, suspension, and chassis. This meticulous attention to detail ensures that when a car undergoes repainting or other cosmetic enhancements through car paint services, it retains its sleek, harmonious lines and curves characteristic of Mercedes design.

Mercedes-Benz Engineering Blueprints: Guiding the Alignment Process

Mercedes-Benz Engineering Blueprints play a pivotal role in the intricate process of Mercedes frame alignment. These detailed blueprints serve as the ultimate guide for technicians, ensuring every adjustment is precise and accurate. By following these meticulous specifications, auto body work specialists can precisely restore the structural integrity of a vehicle, which is paramount for safe and smooth driving.

The blueprint-driven approach not only guarantees optimal vehicle performance but also ensures that any car scratch repair or auto body work aligns with Mercedes-Benz’s high standards. This meticulous process involves intricate calculations and measurements to realign components, ensuring the car’s overall stability and handling are not compromised, even after sustaining damage or undergoing modifications.

Benefits and Best Practices for Optimal Frame Alignment in Mercedes Vehicles

Mercedes frame alignment is a critical process that ensures the structural integrity and safety of Mercedes vehicles. By following Mercedes-Benz Engineering Repair Blueprints, technicians can achieve optimal frame alignment, which offers numerous benefits. Firstly, it minimizes car damage repair costs by preserving the vehicle’s original metal, preventing unnecessary welding or replacement parts. Secondly, accurate frame alignment enhances the precision of auto body painting, resulting in a smoother finish and longer-lasting paint job. This, in turn, increases the overall resale value of the vehicle.

To achieve best practices for Mercedes frame alignment, it’s essential to adhere to strict guidelines. Use specialized equipment designed for precise measurements and adjustments. Ensure the work surface is level and secure to avoid introducing new misalignments. Regularly inspect and calibrate alignment tools to maintain accuracy. Additionally, when dealing with vehicle dent repair, employ techniques that preserve the original panel shape and texture, ensuring a seamless fit once the frame is aligned.

Mercedes frame alignment, guided by Mercedes-Benz Engineering repair blueprints, is a meticulous process that ensures the structural integrity and precision handling of Mercedes vehicles. By adhering to best practices and leveraging these detailed blueprints, technicians can deliver optimal alignments, enhancing both safety and performance for these luxury automobiles. When performed correctly, Mercedes frame alignment becomes a cornerstone of responsible vehicle maintenance, preserving the car’s original design and driving dynamics.